The next step in this refurbishment is to clean the contacts on the rig and lubricate the bears. The primary contact cleaner of choice is DeoxIT D5.

Cleaning the Tube Sockets

I start by cleaning out the tube sockets, I do this by spraying some DeoxIT D5 into the cap and one at a time soaking each of the vacuum tube contacts in the DeoxIT.

After each tube contacts have briefly soaked, I take the tube and wiggle it into the tube socket on the rig and push it into the tube socket then remove it from the socket a few items. This action of using a light bit of DeoxIT sliding it into and out of the sockets works to clean both the contacts on the tubes and each of the tube sockets.

Cleaning the Switch and Variable Resistor Contacts

The last HW-100 rig I rebuilt experienced some output issues when operating in USB mode. After night or two of troubleshooting, I traced the issue back to a corroded contact on the Band switch IR wafer. A little DeoxIT and working the switch back and forth resolved the issue. After this experience I have learned to spend a bit more time being meticulous on cleaning up each of the switch contacts.

For each of the variable resistor and switch contacts I lightly soak a high quality cotton swap with DeoxIT. For high quality cotton swaps I specifically choose swaps where the cotton isnt going to come apart and get stuck inside of the switch, here a little extra money goes a long way. I rub and actuate each of the switches back and forth multiple times, again this back and forth action is what helps to clean the contacts for the switch. Generally I try to avoid spraying DeoxIT directly onto the components but it is required sometimes for difficult to reach areas. Note the spray nozzle rotates to adjust the flow of the spray, generally I use keep this on the L (low) setting.

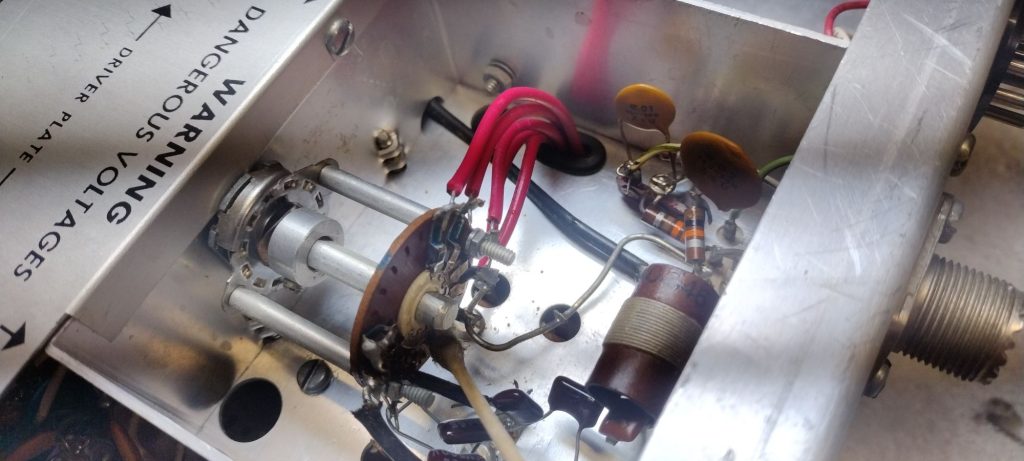

To reach each of the contacts of the Band switch I temporarily remove the bottom shield cover for the Heterodyne Oscillator/Driver Grid/Drive Plate portion of the circuit.

Bearing Lubrication

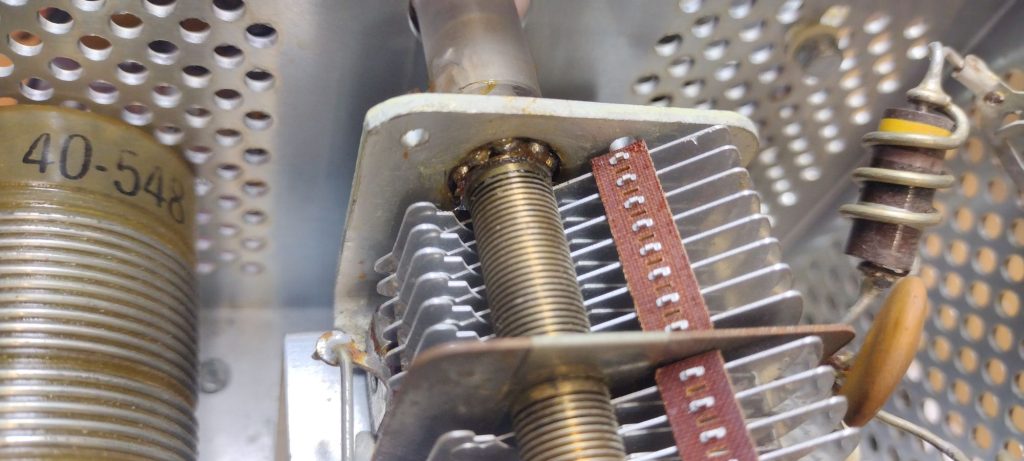

The rig contains a number of different variable capacitors with ball bearings. For these ball bearing I feed some DeoxIT L260 Grease into them. DeoxIT L260 not only acts as a lubricant but also include Aluminum particles to help increase conductivity.

I squirt some of the grease onto the end of a small screw driver, dab the grease into the ball bearings while rotating each of the shafts back and forth. The bottom variable capacitor inside of the RF cage is the most challenging bearings to lubricate. Here I break off the small dowl of wood from one of the discarded cotton swaps, place a small dab of L260 on the end and gently maneuver it into place.

For the next phase we will work to replace the old electrolytic capacitors with something a bit more modern!

’73!